Computer vision and the rise of cloud based AI Inspection tools- A simplified synopsis

The rapid advancement of computer vision and AI-powered visual inspection tools are revolutionizing industries worldwide starting from IBM Maximo Visual Inspection (MVI) to cloud-based solutions.

Maximo is evolving beyond traditional asset management into AI-powered predictive maintenance. MVI allows automated defect detection, reducing manual inspections and improving operational efficiency. As a developer, knowing how to integrate these AI tools with Maximo can set you apart.

Image generated using: Chatgpt

In today’s fast-paced digital world, computer vision is transforming the way industries operate, enabling businesses to automate inspections, detect anomalies, and enhance decision-making. From IBM Maximo Visual Inspection (MVI) to powerful cloud-based AI solutions like Azure Custom Vision, Google Cloud Vision AI, and Amazon Lookout for Vision, organizations are leveraging AI to streamline operations and improve efficiency.

In this article, we’ll explore the evolution of computer vision, compare leading AI-powered visual inspection tools, and discuss how these technologies are shaping the future of asset management, manufacturing, and automation.

Let’s dive in! 🚀

Computer vision is a field of artificial intelligence (AI) that enables machines to interpret and analyze visual data from the world, much like humans do. It uses deep learning and image processing techniques to recognize objects, detect patterns, and make decisions based on images or videos.

In the context of IBM Maximo Visual Inspection (MVI) and similar cloud-based tools, computer vision helps automate quality control, asset monitoring, and predictive maintenance by identifying defects, anomalies, or changes in real time. Industries such as manufacturing, healthcare, logistics, and smart cities are leveraging computer vision to improve efficiency and reduce manual inspection efforts.

Computer vision problems can be categorized into several types, each addressing different challenges related to image and video analysis. Here are the key types:

Image Classification – Assigning a label to an image (e.g., identifying if an image contains a car, cat, or person).

Object Detection – Identifying and locating multiple objects in an image with bounding boxes (e.g., detecting defects in manufacturing).

Semantic Segmentation – Classifying each pixel in an image to identify different objects or regions (e.g., identifying cracks in infrastructure).

Instance Segmentation – Similar to semantic segmentation but differentiates between multiple instances of the same object (e.g., distinguishing between multiple cars in an image).

Anomaly Detection – Identifying deviations from normal patterns, often used in industrial quality control.

Optical Character Recognition (OCR) – Extracting text from images (e.g., reading serial numbers or labels on assets).

Pose Estimation – Detecting the position of objects or body parts in an image or video (e.g., worker safety monitoring).

Action Recognition – Understanding movements or activities in video data (e.g., monitoring worker operations in industrial settings).

Image generated using: Chatgpt

Here are some leading AI-based computer vision tools available in the market:

1. IBM Maximo Visual Inspection (MVI)

Purpose-built for industrial asset management and predictive maintenance.

Supports AI-driven image and video analysis.

Seamless integration with IoT and IBM Maximo EAM.

2. Microsoft Azure Custom Vision

User-friendly AI model training for object detection and classification.

Deep integration with Azure cloud services and IoT.

Customizable models with active learning capabilities.

3. Google Cloud Vision AI

Pre-trained AI models for OCR, object detection, and facial recognition.

API-based approach for scalable implementation.

Strong AI research backing from Google.

4. Amazon Lookout for Vision

Designed for defect detection in manufacturing and industrial applications.

Fully managed service with AWS ecosystem integration.

Automated anomaly detection in images.

5. OpenCV (Open Source Computer Vision Library)

Widely used open-source library for image and video processing.

Supports real-time applications and deep learning integration.

It Can be deployed across cloud and edge environments.

6. TensorFlow and PyTorch (for Custom Vision Models)

Flexible frameworks for building and training custom computer vision models.

Supports deep learning architectures like CNNs and transformers.

Used by researchers and enterprises for advanced AI vision applications.

There are many more tools available in the market and still evolving at a tremendous pace.

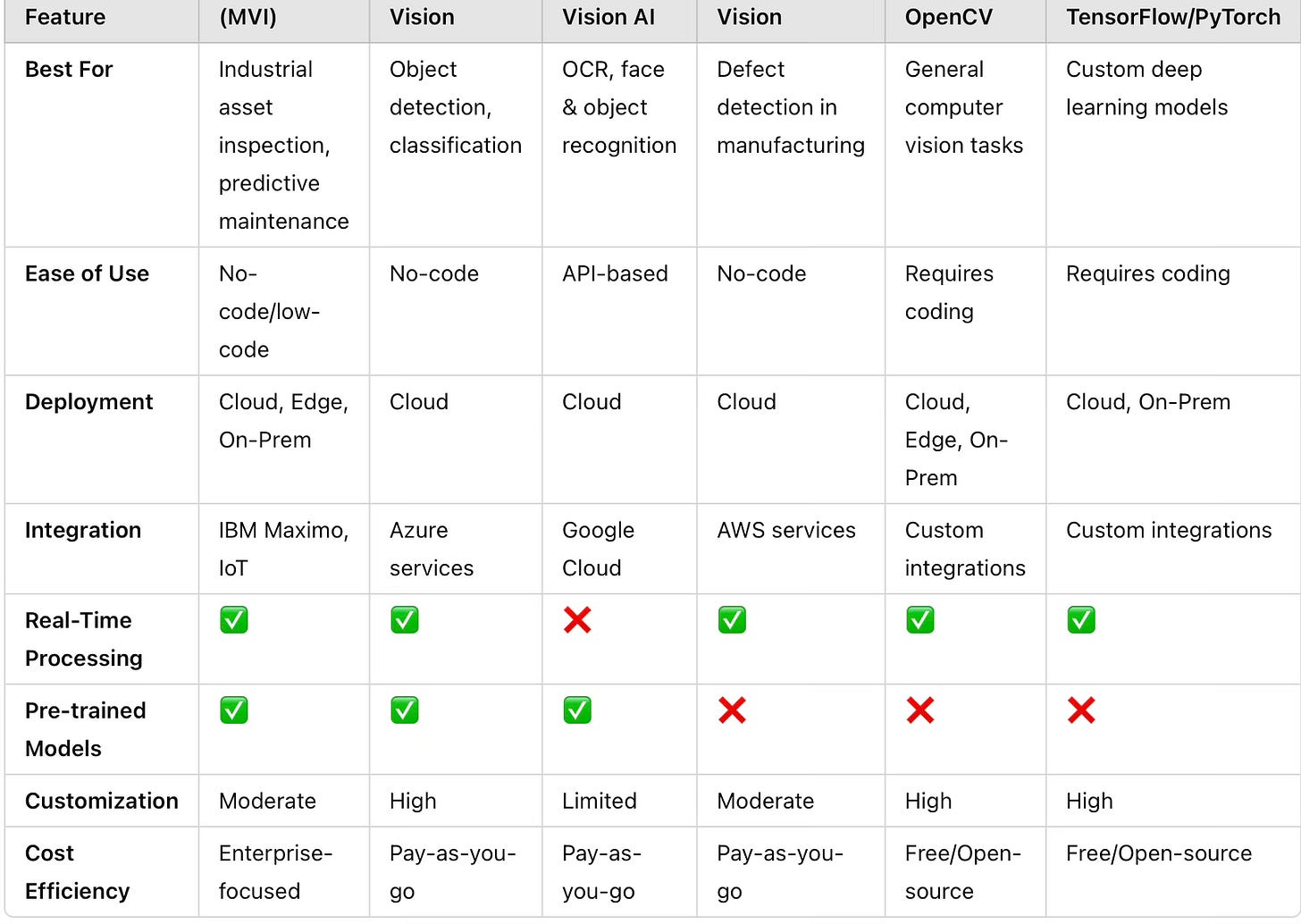

The below table will give a high-level idea of the different products available on the cloud.

How does visual inspection work?

Source: Amazon lookout for Vision.

What is involved in Visual Inspection?

Amazon Lookout for Vision follows a structured process for visual inspection using AI-based defect detection. The different stages involved are:

1. Data Collection & Preparation

Upload images of normal and defective products or components.

Organize images into training, validation, and test datasets.

Ensure images represent real-world variations (lighting, angles, defects).

2. Model Training

Lookout for Vision uses AI to learn from labelled images.

The model identifies patterns in defects and normal conditions.

Users can fine-tune the model by adding more data.

3. Model Evaluation & Testing

Run test images to validate model accuracy.

Identify false positives or negatives and adjust training data if needed.

Amazon provides performance metrics like precision and recall.

4. Deployment & Real-Time Inference

Deploy the trained model in a production environment.

Connect to IoT cameras or inspection stations for real-time monitoring.

Lookout for Vision continuously analyzes incoming images to detect defects.

5. Continuous Monitoring & Optimization

Periodically retrain the model with new defect patterns.

Adjust confidence thresholds to improve accuracy.

Integrate with AWS services (IoT, Lambda, SNS) for automated actions based on detection.

This structured approach allows manufacturers to automate quality control, detect anomalies, and improve production efficiency using AI-driven visual inspection.

TensorFlow/PyTorch can be used for building a fully custom model.

For Maximo developers and asset managers, understanding these technologies is crucial as AI-driven inspection becomes a core part of modern enterprise asset management (EAM). Whether leveraging pre-trained models or integrating custom AI solutions, businesses can significantly improve efficiency, accuracy, and cost savings.

We will keep learning this space and I will share more information on these topics in a simplified manner.

Happy New Year 2025.

References: